100

Skilled Professionals

50

Global and Domestic Clients

13

Years of Experience

3

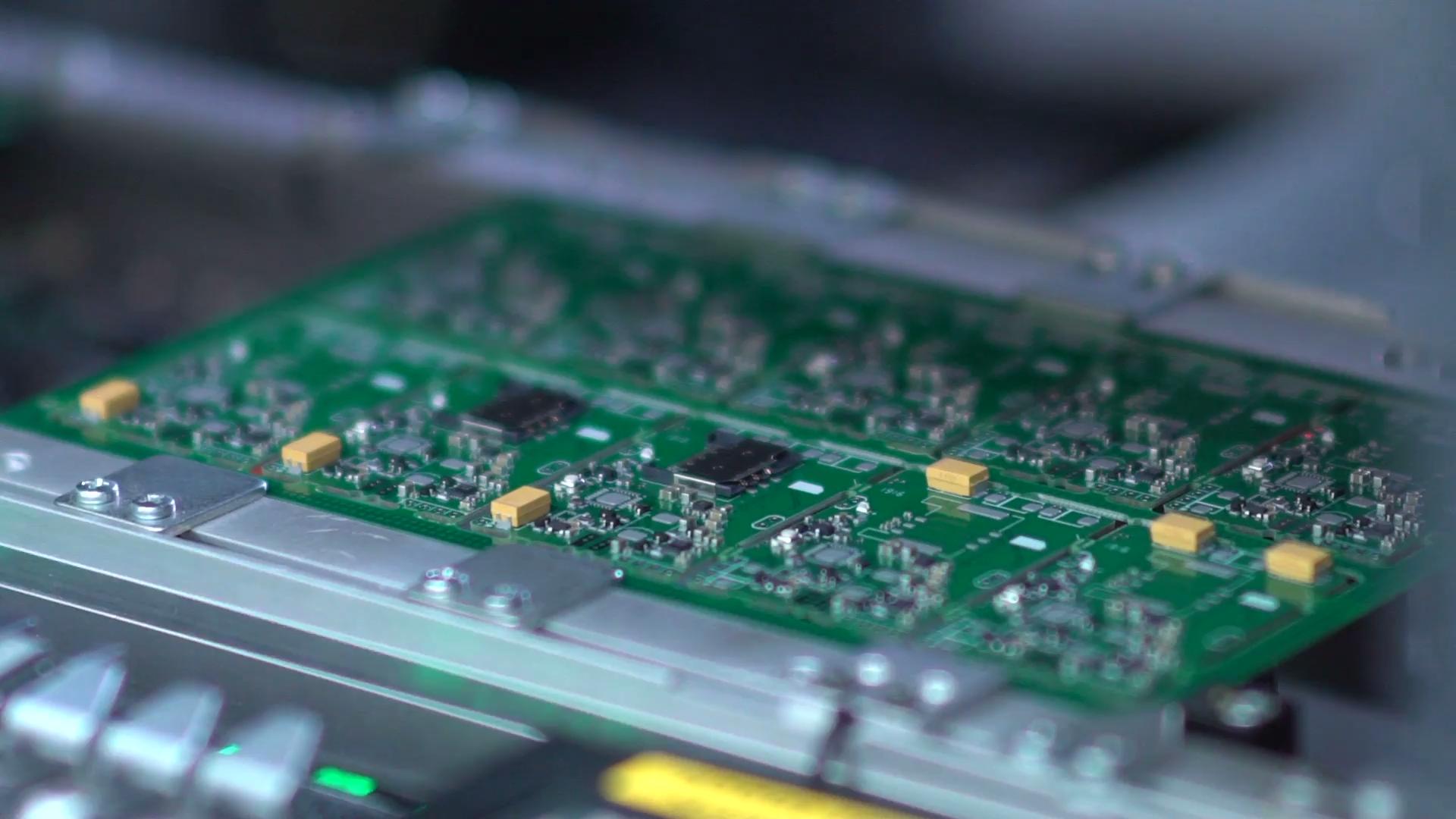

We provide the highest quality electronics manufacturing services to meet your needs, today and for the future.

With over 13 years of experience, we specialize in manufacturing advanced electronics for the automotive, medical electronics, aerospace, and IoT industries. Utilizing SMT, BGA placement, and AOI, we focus on delivering high-quality PCB production backed by rigorous quality assurance and industry certifications.

With over 13 years of experience, we specialize in manufacturing advanced electronics for the automotive, medical electronics, aerospace, and IoT industries. Utilizing SMT, BGA placement, and AOI, we focus on delivering high-quality PCB production backed by rigorous quality assurance and industry certifications.

Our dedicated team assists you from prototype assembly, testing to final production, offering valuable insights and guidance at every stage.. Exclusive space provided for customers to test PCBAs in micron NPI lab.

Read More

Collaborating with you during the prototype phase, we provide feedback and recommendations to optimize your PCB designs and box builds for efficient manufacturing processes.

Read More

From concept to reality, we excel in crafting mechanical designs, metal fabrication & plastics through our partners that seamlessly integrate with your electronic systems.

Read More100

50

13

3

At Mircon EMS, we are committed to delivering high-quality electronics manufacturing solutions while maintaining the highest ethical standards. We believe in transparency, integrity, and dedication to our clients. We never compromise on quality or professionalism, ensuring that every project we undertake meets global standards of excellence.

We are proud to be a part of the Government of India's Make in India initiative. By leveraging India's robust manufacturing ecosystem and promoting localization and indigenization, we provide our clients with a significant competitive edge, empowering them to excel in the global marketplace while supporting domestic growth and innovation.

Meet our people. See our work. Join our team.